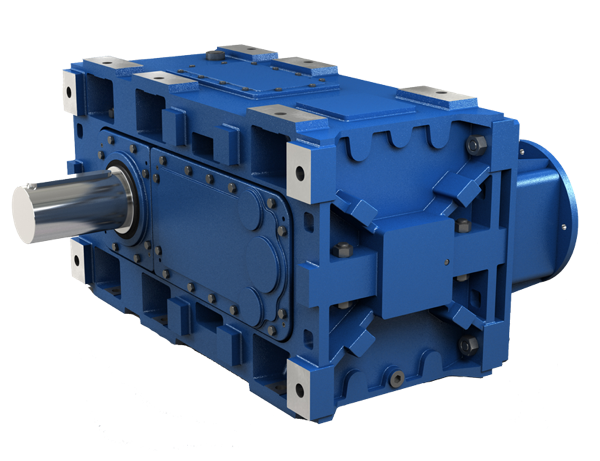

PBZ

Continous Duty with Reduced Maintenance CostsThe PBZ series consists of parallel helical and bevel-helical gear reducers up to 4 reduction stages, characterised by high power density, compact size, modularity, reliability and a favourable performance/sturdiness ratio.

These industrial gear reducers have been conceived and designed for continuous, critical and particularly arduous applications requiring a high number of accessories, as well as dedicated options for specific fields: PBZ units perfectly meet all these needs, fully satisfying the heavy-duty industry world.

Warranty: Two years from date of delivery.

CHARACTERISTICS:

- Sizes: 179, 199, 219, 249, 269, 279, 319, 349, 399, 409

- Gearing: 2, 3, and 4 stages for parallel gear reducers, and 3, and 4 stages for helical bevel gear reducers

- Nominal output momentum 110,000 Nm (n1= 1400 rpm)

- Available input versions: P – with bell gear and joint, I – with solid shaft

- Available output versions: HC - hollow output shaft with key slot HL - hollow output shaft with locking unit CS - cylindrical solid output shaft with key CD - cylindrical double outlet solid output shaft with key

- Gears and sprockets: hardened and case-hardened 21NiCrMo2 steel

- Reduction ratios: ranging from 6 to 419

- EN-GJS400-15 UNI EN 156 cast-iron casing

- Outer protection with two-component water-based paint, minimum coat thickness 80 microns

- RAL 5010 blue